ESTIMATE OF PORTLAND CEMENT CONCRETE

STRENGTH BY MATURITY METHOD

GENERAL

This IM outlines the procedure for using the maturity concept as a nondestructive method to estimate concrete strength.

Determination of concrete maturity (time temperature factor (TTF)) and estimating in place concrete strength is a two-step procedure as follows:

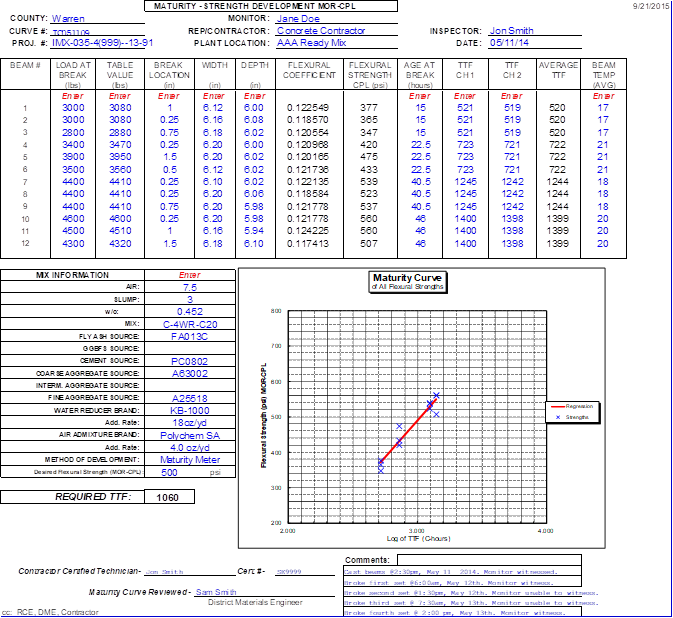

- Maturity Curve - A relationship must be established between the maturity (TTF) and the concrete strength as measured by destructive methods (that is, through testing of beams or cylinders). The development of the maturity-strength curve shall be done at the plant site at the beginning of construction using project materials and the project proportioning and mixing equipment.

- Field Maturity - The second step is the temperature monitoring of the placed concrete. Temperature probes are installed in the concrete and the temperature is measured. From those measurements, along with the age at which the measurements were taken, the maturity (TTF) is calculated and used to estimate the concrete strength. A maturity meter may also be used to determine the maturity value (TTF).

For concrete furnished from a construction or stationary mixer, which is in place prior to construction of the specified project, a maturity curve may be established ahead of actual construction of the specified project. The test specimens shall be cast with concrete made from the same plant and using the same materials source as will be used in the specified project. The agency shall be informed and have an opportunity to observe the development of the maturity curve and validation.

THE MATURITY CONCEPT

The hydration of cement and gain in strength of the concrete is dependent on both curing time and temperature. Thus, the strength of the concrete may be expressed as some function of time and temperature. This information can then be used to determine the strength of concrete without conducting physical tests. The time-temperature function commonly used is the maturity concept proposed by Nurse-Saul (ASTM C1074),

M (oC x hours) = ∑ [(T – T0) ∆t]

Where M is the maturity in oC-hours [M is also termed the time-temperature factor (TTF)], Δt is the time interval in hours (or days), T is the average concrete temperature during the time interval Δt, and T0 is the datum temperature at which concrete ceases to gain strength with time. The value of T0 = (-10oC) is most commonly used. As a result, Equation 1 becomes:

M (oC x hours) = ∑ [(T + 10) Δt] Equation 2

EQUIPMENT

· 12 - 6 in. x 6 in. x 20 in. or 4 in. x 4 in. x 14 in. beam molds

· 1 each shovel (square point), rubber hammer or equivalent, and wood float or equivalent

· Hydraulic testing machine – center point loading flexural

· Maturity meter – a device that automatically measures, records, and displays the maturity (TTF) value

· Hand-held thermometer - a temperature measuring device with a thermocouple wire or probes readable to the nearest 0.1°C and accurate to 1°C.

· Temperature data logger – a device that measures temperature and electronically stores the readings a minimum of once per hour

ESTABLISHMENT OF MATURITY-STRENGTH RELATIONSHIP - MATURITY CURVE

To establish a maturity-strength relationship for a concrete mix, a maturity meter and a hydraulic testing machine are needed. The following procedure shall be used: (NOTE: Before using any maturity meter, check to be sure the datum temperature is set to -10ºC.)

1. Cast a minimum of twelve beams, as per IM 328. Test the entrained air content of the concrete being used to cast the beams, as per IM 327. Record these values. The concrete shall meet specifications, with a minimum air content of 5.5%. There is a direct relationship between w/c ratio and strength. The concrete used to develop the maturity-strength relationship shall be at the maximum w/c ratio expected during production, or within 0.02 of the maximum w/c ratio of the mix design. The beams shall be cast from a batch of at least 3 cu. yd.

2. When using thermocouple wire, strip ½” to ¾” of the coating from each end of the two wires and twist ends. Embed a thermocouple wire near each end of a test beam (when flexural strength is to be determined) to monitor the temperature. This beam will be the last to be tested. A probe shall be inserted near each beam end to the approximate mid-depth and such that they are approximately 3 in. from each side and each end of a 6-inch beam (or 2 inches for a 4 inch beam). Loop the wire around the beam box handles to prevent the wire from being inadvertently pulled out of the beam. The average of the two readings will be used in the development of the maturity-strength curve. A maturity meter shall be used to develop the curve. A temperature data logger may be used to develop the curve and the maturity (TTF) shall be calculated from hourly readings.

3. At the plant site, cast beams according to IM 328 and test them according to IM 316. Concrete used for casting beams must have a temperature above 50°F. Immediately after casting, cover the beams with wet burlap and plastic to prevent moisture loss. At an age of 16 to 24 hours remove forms and store the specimens in a wetted sand filled pit of adequate size to accommodate all specimens made. Place the specimens on a reasonably smooth bed of sand and cover them completely with additional sand. The meter can be stored in a lab trailer or vehicle with the probes run outside to the beam in the sandpit. The DME may allow concrete produced at a ready mix to be delivered and tested at a central laboratory, as long as specimens are cast and cured within 90-minute time limit.

It is critical that the specimens be maintained in a continually wet condition, and above 40°F after casting until they are tested. They may be protected while in the forms by placing foam board or plywood underneath them and covering with insulating blankets or by placing them inside a heated enclosure. If the temperature in the sand filled pit cannot be maintained above 40°F, remove the specimens and place them under wetted burlap in a heated enclosure or in lime saturated water controlled between 60 and 80 °F. NOTE: Lime-saturated water is prepared by mixing 0.4 ounces of hydrated lime with 1 gallon of water. Hydrated lime should be a minimum of 90 percent calcium hydroxide (CaOH).

4. Determine maturity (TTF) and strength values at four different ages. Test three specimens for strength at each age and calculate the average strength at each age. The maturity (TTF) value shall be calculated from a temperature reading at the time the specimen is tested for strength. The tests shall be spaced such that they are performed at somewhat consistent intervals of time and span a range in strength that includes the opening strength desired. Ideally, there would be at least two sets of strength values below the opening strength. For Class C or QMC mixtures, the first set of beams will typically be tested at an age of approximately 8 to 12 hours, depending on concrete temperature. Test age may need to be increased when concrete temperature is below 50 °F, when retarders are used, or when high replacement mixes are used. Test age may need to be decreased at higher temperatures above approximately 80°F. The average strength of the first set of beams must be less than 425 psi for the curve to be valid.

If the maturity curve is intended for use in determining the time to begin joint sawing, additional test specimens will need to be cast and strength testing must begin at lower maturity values.

For pavements, a minimum flexural strength of 500 psi is required for opening. (See Article 2301.03). For structural concrete, a minimum flexural strength of 575 psi is required before forms may be removed and concrete may be subjected to flexural loading. Strength requirements vary for determining when forms for roofs of culverts may be removed (See Article 2403.03). Testing intervals may need to be increased over those for paving.

For structural concrete where compressive strength of 4500 psi or greater is required, develop a maturity curve utilizing cylinders for compressive strength. Ensure the last set of cylinders is greater than the required design strength. Cast and cure, in accordance with IM 315, a minimum of 15 cylinders and place probes in two of the cylinders. Test a set of three cylinders at each age of 1, 3, 7, 14, and 28 days (or earlier if already above design strength). This maturity curve may be utilized for other units with lower compressive strength requirements. The DME may also approve this curve for items with flexural strength requirements.

5. Plot the measured strength against the corresponding values of maturity at different ages, as determined by the maturity meter or by hand methods. Use the spreadsheet provided by the District Materials Concrete Technician to determine maturity-strength relationship. The maturity (TTF) value corresponding to the required opening strength shall be used to determine when the pavement or structure may be loaded. An example of the Maturity-Strength Development form, generated by the computer program, is included at the end of this IM. This form shall be reviewed by the DME. Copies will be provided to the Project Engineer, DME, Concrete Materials Engineer, and the contractor.

FIELD MATURITY (TTF) PROCEDURE – Estimate in place concrete strength

Placement of the Temperature Probes

Strip ½” to ¾” of the coating from each end of the two wires and twist the ends together before inserting them into the fresh concrete.

Pavements

For pavements, insert the temperature probe into the concrete until the end is at approximately the pavement mid-depth and 1.5 feet from the edge of the pavement. The wire ends are the points at which the temperature measurement is taken. Insertion may be accomplished by attaching the wire ends to a wooden dowel and embedding it into the slab. Check to ensure the concrete is consolidated around the dowel. The portion of the dowel that protrudes above the pavement should be cut or broken off after the testing is completed.

Probes may be placed at any point along the pavement slab. A minimum of two probes shall be placed in each day's placement with one at the end of the days run. On days when there is a large difference between daytime high temperatures and nighttime low temperatures, placing additional probes near the beginning of the day's run and at a point near the midday location provides useful information. The concrete placed during the middle of the day can gain strength faster than the concrete placed at the beginning of the day because of daytime heating. Place probes at side roads, or other locations, where opening to traffic is critical.

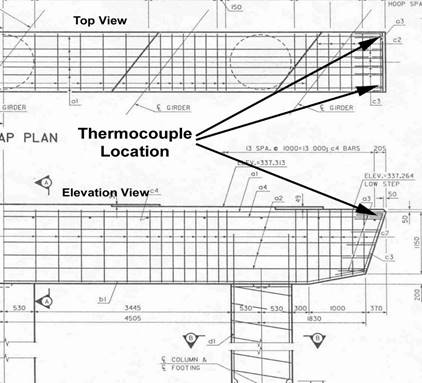

Structures

For structures, a minimum of two probes shall be attached to the reinforcing steel near the edge at the upper corner of the exposed surface. (See Figure 1 at the end of this IM.) The probe should be wrapped around the rebar and taped with approximately 1 to 2 inches extending below the rebar to prevent the probe from damage and removal during concrete placement. The rebar should also be taped 2 to 3 inches on both sides of the probe location to prevent contact with the reinforcing steel. (See Figure 2 at the end of this IM.)

Temperature Data Collection and Maturity (TTF) Calculation

Handheld thermometers (Pavements)

Typically, a handheld thermometer is used to collect temperature readings for pavements. The probe wire ends, extending out from the concrete, may be connected to a plug. A plug with thermocouple wires and clips attached to the handheld thermometer may also be used to connect to the wires extending from the concrete. Be careful to connect the copper wire to the copper plug prong (+).

Once the wires are placed, an initial temperature of the concrete shall be taken and recorded. Temperature readings should be taken in the morning and late afternoon as a minimum for standard A, B and C mixtures. For the fast-setting mixtures, readings should be taken every few hours, depending on weather conditions and mixture.

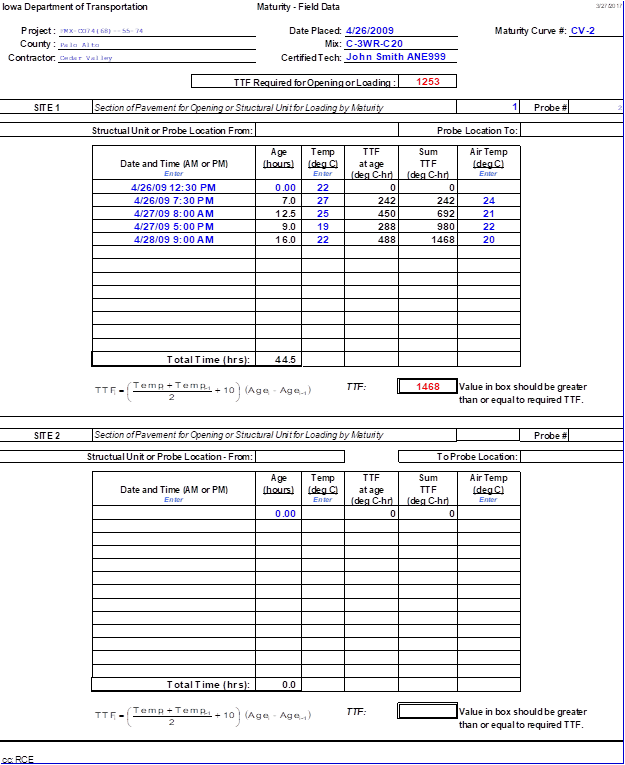

A Maturity Data Recording Sheet, provided at the end of this IM, may be used to record the temperature readings and calculate the maturity values.

A continuous temperature data logger is required for monitoring structures. The maturity value shall be calculated based on hourly readings obtained from the device. The device may also be used for monitoring pavements.

If a maturity meter is being used to monitor either pavements or structures, it should be connected to the probe as soon as possible to begin data collection. The maturity (TTF) value may be read directly from the maturity meter. Some maturity meters are not moisture proof and will be permanently damaged if not protected from water or moisture.

It is the responsibility of a Level I PCC technician to place probes, perform all calculations, and submit forms to the Engineer. The Level I PCC technician may supervise other personnel to place probes, obtain temperature readings or read maturity values.

Implementation

For pavements, it is the intent of the procedure to use the maturity method to open the pavement to traffic from the first day of paving, including the days of development of new curves.

During maturity curve development, a preliminary maturity TTF value may be used to determine opening strength of pavement placed during the first day of paving.

The preliminary TTF will be the TTF value, at a particular age when the average strength of the three beams used for development of the strength-maturity curve meets or exceeds the required opening strength.

After curve has been established and approved by the DME, only the approved maturity TTF value shall be used to open pavement sections. When commercial maturity sensors are used, submit reports displaying time versus TTF.

In all cases, the Engineer will determine if adequate strength has been achieved and the time when a pavement may be opened to traffic based on TTF measurements collected from that pavement.

When multiple plants are being used in accordance with Article 2301.02.C,4,a, use the most conservative curve (highest opening TTF) to determine when the pavement may be opened. Use the most conservative curve if multiple cement changes have occurred.

A maturity curve developed at a plant from the same company may be transferred to another plant of the same company provided identical sources of materials are used. The transferred curve shall be validated at other plants within the company. Central batch plants from the same company shall develop a maturity curve.

For structures, since maturity is to be used on units exposed to flexural loading, the maturity curve should be developed early in the project during placement of concrete exposed to compressive stress. If this is not possible, concrete placed on the same day as development of the strength-maturity curve may be loaded at a particular age using either of the first day placement criteria required for pavements.

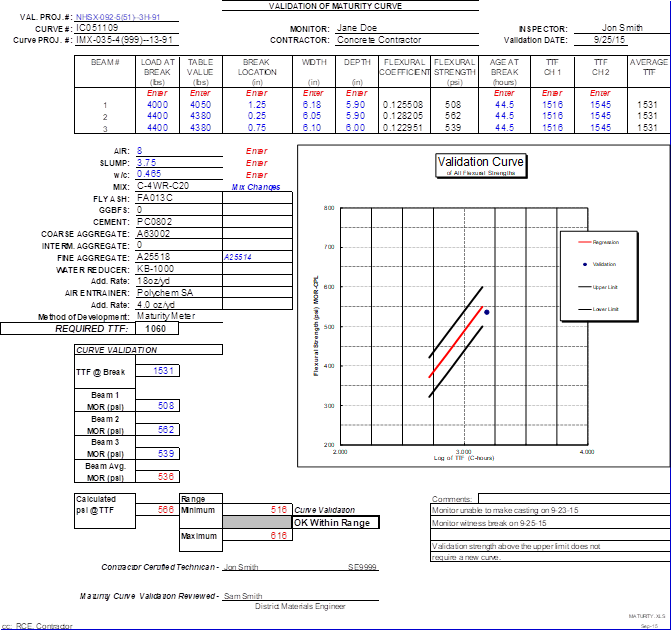

Curve Validation

A curve validation is required once every 90 calendar days during normal plant production. If the plant has not supplied concrete to the project for a period of greater than 90 days, the curve may begin on the first day of startup. The validation tests shall be conducted to determine if concrete strength is being represented by the current maturity curve. Cast and cure three (3) beams using the same procedure and manner as used to develop the current maturity curve. Test all three beams as close as possible to the maturity value determined to represent the opening strength of the pavement or the flexural loading strength or form removal strength of the structure. Normal production concrete may be used for curve validation.

Pavements and Structures Flexural Strength

For pavements and structures, if the average calculated strength value at the TTF the validation beams were tested is within the range of ±50 psi of the original curve, the original curve shall be considered validated.

Structures – Compressive Strength up to 4000 psi

For structures, if the average calculated strength is greater than the original curve at the TTF the validation beams were tested, the original curve shall be considered validated.

Structures – Compressive Strength 4500 psi or greater

A curve validation is required once every 90 calendar days during placement of concrete with compressive strength requirement of 4500 psi or greater. If the average calculated compressive strength is greater than the original curve represented by the cylinders tested, the original curve shall be considered validated.

An example of the Validation of the Maturity Curve is included at the end of this IM. Copies shall be provided to the RCE, DME, and the contractor.

This validation procedure is a check to ensure the mix is basically the same as originally tested. If the test results indicate a new curve must be developed, this should be done in a timely manner. The curve currently being used shall be continued until new beams can be cast and at that point the implementation procedure described above shall be followed.

Factors Requiring a New Curve

Changes in material sources, proportions, and mixing equipment all affect the maturity value of a given concrete mixture. Examples: Mixes with Type IS or IP cements exhibit slower strength gain than with Type I or II cements and mixes with Class F fly ash exhibit slower strength gain than with Class C fly ash. Development of a new maturity curve due to material source or proportion changes in a concrete mix may be waived by use of the validation procedure. Note: C-3WR and C-4WR mixes are similar enough that separate curves are not required. DME may allow C-WR curves to be utilized for C-3 or C-4 mixes.

The following will require a new curve to be developed:

· For the validation beams tested, the average calculated strength at the TTF tested is below the minimum range (-50 psi) of the original maturity curve.

· The w/c ratio of the production concrete exceeds the w/c ratio of the concrete used to develop the strength-maturity curve by more than 0.02.

Maturity Meter Calibration

The four channel Type T thermocouple (Humboldt or Gilson type) maturity meters shall be calibrated yearly to ensure proper temperature sensing. The calibration may be performed at the Central Laboratory before the start of each construction season. To ensure accurate temperature measurement, handheld thermometers should also be checked at least yearly against a certified thermometer or other calibrated meter at the District or Central Laboratory. Some maturity meters may need to be sent to the manufacturer for calibration.

For commercial maturity meter sensors or temperature sensors used directly in the pavement or structure, submit calibration records from the manufacturer, for the sensors used, to the engineer.

Figure 1. Typical thermocouple location placement in pier cap

Use similar method for thermocouple placement in other structural elements.

Figure 2. Typical attachment of thermocouple to reinforcing steel