CHAIN-LINK FENCE AND FIELD FENCE

GENERAL REQUIREMENT

All fence material shall be new and

shall comply with the requirements of the standard specifications

Section 4154.

Statement of conformance shall be included with each shipment to each project.

ACCEPTANCE CHAIN LINK FENCE

Acceptance of posts, braces, rails and fabric for chain link fence shall be on the basis of certification from approved sources and on the basis of satisfactory test results.

Approved Sources for chain link fence materials are listed in Appendices A, B and C of this IM.

All Fence materials shall be from domestic origin melted and manufactured in the USA.

For alternate shapes and coating materials, refer to the Acceptance of Alternate Materials Section of this IM.

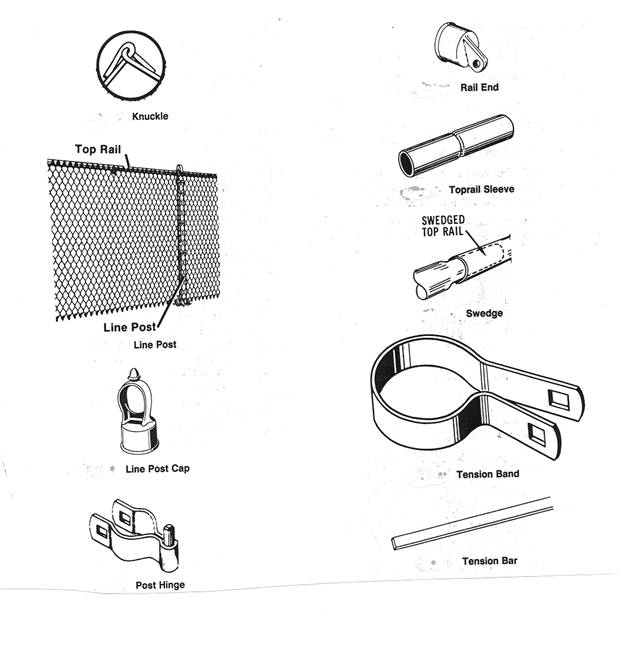

POSTS, BRACES, RAILS AND GATES FOR CHAIN LINK FENCE

1. Tubular (Pipe) materials shall be from approved sources and shall be galvanized or aluminum coated, straight, one piece free of welded sections (no spliced sections) and free of any defects with a minimum tensile strength of 48,000 psi (330 MPa) and minimum yield strength of 30,000 psi (205 MPa).

2. Galvanized Tubular Posts, rails and braces shall meet the requirements of Table 1 of ASTM F-1083 (Schedule 40) and shall be galvanized inside and outside by the hot dip process meeting the requirements of ASTM A 123 and the galvanizing shall be uniform, free of voids or excessive roughness. The average zinc coating shall not be less than 1.8 oz / ft2 (550 g/ m2)

NOTE: Tubular Posts, shall be furnished with an approved cap. (Article 4154.10)

NOTE: Rails top, bottom, intermediate or brace rail. (Article 4154.10)

3. Aluminum coated posts, rails, braces, and gate frames shall have a minimum coating of 0.75 oz per square foot and shall meet the requirements of Article 4154.10B2 and AASHTO M 181

4. Galvanized brace wire, Tie wire and tension wire shall meet the requirements of Article 4154.05 of the standard specifications. Galvanized brace wire shall meet the requirements of ASTM A116 Class 3 coating or aluminum brace wire with a coating of not less than 0.25 oz / ft2 use wire size # 7 tension wire, use wire size #9 brace wire, use wire size #12 clips.

5. Special fittings for chain link fence/braces, diagonal tension rods, round steel roads, lock devices) shall meet the requirements of Article 4154.11 of the Standard Specifications.

6. Gates for chain link fence shall meet the requirements of Article 4154.12 of the Standard Specifications.

7. Pipe weight, wall thickness and diameter shall meet the requirements of table 1 of ASTM F 1083, schedule 40.

8. Deer fence, shall meet the requirements 4154.12B

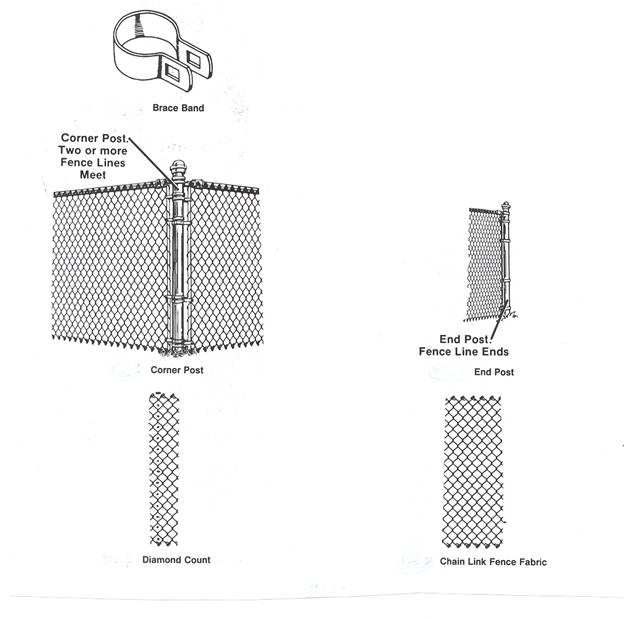

FABRIC FOR CHAIN LINK FENCE

1. Chain Link Fence Fabric – unless otherwise specified on the plans, fabric can either be zinc coated fabric meeting the requirements of ASTM A 392, class 2 coating (minimum 2 oz / ft2 (611 g / m2)) or aluminum coated fabric meeting the requirements of ASTM 491 (minimum 0.40 oz/ft 2 (122 g/m2 )). (Article 4154.03), for wire size 0.192”, or 0.148” or 0.135”

2. Wire for the fabric shall have a minimum breaking strength 1290 lbf (5740N), for wire size 0.148” or wire size 0.135”.

Note: The required minimum breaking strength shall include both Type I Aluminum coated and Type II Zinc coated.

CERTIFICATION, SAMPLING AND TESTING

1. Material Certification - from producer or supplier shall be required on a project-by-project basis stating that the materials supplied meet the requirements of these specifications.

2. Samples - A minimum of one sample per project per year shall be required.

3. Test samples from a project shall be a minimum of 36” – 48” (915 - 1220-mm) in length and shall represent posts, top rail and brace material of the same lot. Samples shall be tested for tensile, yield strength, and for wall and coating thickness.

4. Fabric Test samples shall represent a cross section of a minimum of 12-in. x 72-in. (305-mm wide x 1830-mm high) of the same lot. Samples shall be tested for breaking strength.

5. Identifications - samples identifications are required and shall state the source, origin, manufacturer and whether they are zinc or aluminum-coated. Copy of the mill certification shall be included along with the sample identifications.

ACCEPTANCE OF FIELD FENCE

1. Steel line posts for field fence shall meet the requirements of Article 4154.09.

2. Barbed wire shall meet the requirements of Article 4154.04. Staples used to attach fence to wood posts shall be plain, class 3 zinc-coated meeting the requirements of Article 4154.06

3. Wood fence posts shall be pine posts meeting the requirements of section 4154.07 and 4164 and shall be treated wood posts. Approved sources of treated wood post are listed in IM 462 Appendix A

4. Braces for field fence steel angles shall meet the requirements of Article 4154.08. Approved sources are listed in Appendix D of this IM. Field fence braces weight shall not be less than 1.94 lbs per foot or (2.9 kg / m). Angles shall be no less than 2” x 1 ½” x 3\16”.

5. Field Fence Fabric shall meet the requirements of ASTM A 116 Type Z, Class 3 coating. Note: Type Z is made from Zinc Coated Wire (Article 4154.02) ASTM Design # 10411-6-11 Grade 60- wire or Design # 1047-6-12 ½ Grade 125 wire or ASTM Design # 939-6-11 Grade 60 wire or 939-6-12 ½ Grade 125 wire.

6. Staples used to attach field fence fabric to wood posts, shall be plain, class 3 zinc coated No. 9 (3.76 mm 1 ¾” (45 mm) long wire staples.meeting the requirements of Article 4154.06

PRODUCT APPROVAL OF

ALTERNATE MATERIALS

1. Alternate materials shall be accepted on the following basis:

a. Application made in writing to the Office of Materials.

b. Certification from fabricator and / or supplier

c. Test data for bending and stiffness

d. A 2.0 foot sample

e. Salt spray testing of coating other than zinc or aluminum coating.

f. Mixing galvanized and alumini9zed components shall not be allowed.

2. ASTM F 1043 can be accepted as an alternate material for use in chain link fence framework on the following basis:

a. Materials shall be of either Group 1A (round steel pipe) or Group 1C (round steel pipe electric resistance welded pipe).

b. Post materials shall be galvanized steel of the standard weight – schedule 40 and of the nominal sizes listed in ASTM F 1043.

c. Minimum yield strength for Type 1A shall be 30,000 psi (205 MPA) and for Type 1C shall be 50,000 psi (344 MPA)

d. All other dimensional requirements (outside diameter, radius, wall thickness) shall be in accordance with ASTM F 1043.

e. The weight of zinc coating for exterior and interior coating shall not be less than 1.8 oz/ft2 (550 g/m2), minimum average in accordance with ASTM F 1043.

f. Zinc coating for roll-formed shapes shall be in accordance with the requirements of ASTM A 123 / A 123M (Hot Dip methods) Grade 45 or 50, except with a 2.0 oz / ft2 (610 g/m2) minimum average for zinc coating.

Note: Maximum allowable heights of frame work and post spacing are to be based on chain link fence fabric mesh size, gage, and specified wind loads. (Post spacing are not to exceed 10 ft).

g. “C” Section Posts shall meet the requirements of ASTM F-1043, Group II, Schedule 40 and shall be galvanized by the hot dip process. The average weight of zinc coating shall not be less than 1.8 oz per square foot. “C” section posts furnished to these specifications shall have a minimum tensile strength of 50,000 psi (344 MPa). “C” Section posts shall be made from steel melted and manufactured in the USA.

3. Polyvinyl coated chain link fence shall be accepted on the basis of certification from approved sources as required by the contract document.

4. Polyvinyl Chloride and other organic polymer coatings will be designated as Polymer coating and shall meet the requirements of ASTM F 668 Class 1, Class 2A, or Class 2B.

Note: Polyester powder coating may be used with prior approval of the engineer.

5. Polymer coated posts, rails, gates, fabric, and wire shall have the polymer coating applied over galvanized substrate. Polymer coating shall be Type IV meeting the requirements of AASHTO M 181.

6. Polymer coated brace wire, Tie wire and tension wire shall meet the requirements of ASTM F 668, Class 2B.

7. Polyvinyl coated fabric shall meet the requirements of ASTM F 668 Class 2b and the standard colors of ASTM F 934 as specified in the contract document.

8. The process for producing Class 2 B polymer or polyvinyl coating requires the use of a primer to obtain a proper chemical bonding to the substrate as per manufacturer recommendations.