Acceptance of stainless steel bolts, studs, rods, hex cap screws, nuts and washers shall be on the following basis:

1. Certified mill test report

2. Approved sources (listed in Appendix A) shall be on the approved list prior to the letting.

3. Sampling and testing by the Iowa Department of Transportation.

4. Compliance with article 4187.01C of the Standard Specifications and the followings ASTM requirements.

REQUIREMENTS

- Stainless Steel Bolts, Studs and Hex Cap Screws

1. Shall comply with the requirements of ASTM A320/A320M, class1, grade B8, class 1A, grade B8A or class 2 grade B8 or ASTM F593 group 1, alloy 304 or 304 L, group 2, alloy 316 or 316L, or group 3, alloy 321 or 347 meeting condition A, Cw1 or CW2

2. Use hexagon bolt heads

3. Threads are to comply with the requirements of ANSI/ASME B1.1 for UNC thread series, class 2A tolerance.

4. Use the size and the type specified in the Contract Documents.

- Stainless Steel Nuts and Jam Nuts

1. Nuts and jam nuts shall comply with the requirements of the ASTM A194/ A194 M, grade 8, 8A, 8C, 8CA, 8M, 8MA, 8T or 8TA, or ASTM F594, group 1, alloy 304 or 304L, group 2, alloy 316 or 316L, group 3 alloy 321or 347, meeting condition A, CWI or CW2

2. Same alloy properties as the specified for bolts shall be required for nuts and jam nuts (ie group alloy, class and condition)

3. Use hexagonal nuts and jam nuts.

4. Threads shall comply with the requirements of the ANSI/ASME B1.1 for UNC threads series, class 2B tolerance.

5. Unless otherwise specified, shall comply with the dimensional requirements of ANSI/ASME B18.22.1

C. Stainless Steel Washers

1. Stainless steel washers shall comply with the requirements of ASTM A240/A24M.

2. Same alloy properties as the bolts and nuts shall be required for the washers (ie group alloy, class and conditions)

3. The engineer may approve washers with dimensions other than those specified

4. Shall comply with the dimensional requirements of ANSI/ASME B18.22.1 for bolts specified

D. Stainless Steel U Bolts

- Stainless steel U bolts shall comply with the requirements of ASTM A320/A320M, Class 1 Grade B8, Class 1A Grade B8A or Class 2 Grade B8 or ASTM F593 Group 1, alloy 304 or 304L, Group 2 alloy 316 or 316 L or group 3 alloy 32I or 347 meeting conditions A, CWI or CW2

- Threads shall comply with the requirements of the ANSI/ASME B1.1 for UNC thread series, class 2A tolerance and the dimensional requirements of ANSI/ASME B18.22.1

- Stainless steel nuts and jam nuts shall comply with the same requirements as stated in section B of this IM.

- Stainless steel washers, shall comply with the same requirements as stated in section C of this IM.

5. Use the same alloy class, group, and conditions as the bolts, nuts and washers.

Properties Stainless Steel Fasteners

Lock Type Washers and Jam Nuts must be specified and used with all stainless steel fasteners. Lock washers must be placed under the nut to help reduce loosening due to structure vibration and load fluctuation.

Stainless steel fastener components shall be protected from the elements, dirt and moisture in closed / sealed containers at the site of installation.

Stainless steel fasteners shall be lubricated. No dry fasteners shall be allowed to be used. Fastener components shall not be cleaned of lubricant that is present when delivered to the project site.

Components that accumulate rust or dirt resulting from the processing plant or job site shall not be incorporated into the project.

Stainless steel fasteners shall be of a domestic origin, melted and manufactured in the USA.

Installation Bolt Fasteners

All Bolts and miscellaneous fasteners shall be installed in accordance with either the requirements of the design plans, established industry practice, or manufacturers recommendations.

A common bolted connection in ancillary structures consists of bolted flange or face plates that match face-to-face, such connections occurs at tense chord splices, long mast arm splices, and arm to pole connections.

Unless otherwise specified, and / or approved by the engineer, compressible materials such as gaskets, insulation, metal shims shall not be allowed to be placed between any bolted connection and should not be placed between any flanges.

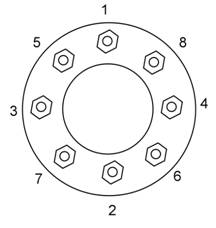

Tightening of bolts should be performed in a manner that brings the faying surfaces up evenly. Unless otherwise specified differently in the design plans, a star tightening pattern is recommended (with the approval of the engineer)

Snug-tightened Condition

Snug-tight condition is defined as the tightness that is attained with a few impacts (3 5) of an impact wrench or full effort with an ordinary spud wrench that brings the connected plies into firm contact.

Note #1: There should not be any surface visibly not in contact after snugging the bolts.

Note #2: Bolts to be tightened only to the snug-tight condition shall be clearly identified on the design and erection drawings.

Note #3: Its highly recommended and it could be beneficial to the state and as well to the contractor to perform torque / tension testing to establish the tension being provided for specific torques.

Inspection of Snug-tightened Joints

After the connections have been assembled, it shall be visually ensured that the plies of the connected elements have been brought into firm contact and that washers (lock washers) have been used as required, there should be no further evidence of conformity is required for snug-tightened joints.

Summary of the inspection requirements for snug-tightened joints shall consists of the followings:

1. Verification that the proper fastener components were used

2. The connected elements were fabricated properly

3. The bolted joint was drawn into firm contact

Torque Values for Stainless Steel Bolts

|

Bolt Size |

Type 304 (ft lb) |

Type 316 (ft lb) |

|

|

|

|

|

1/4 |

6.0 |

7.0 |

|

5/16 |

11.0 |

12.0 |

|

3/8 |

20.0 |

21.0 |

|

7/16 |

31.0 |

33.0 |

|

1/2 |

43.0 |

45.0 |

|

9/16 |

57.0 |

59.0 |

|

5/8 |

93.0 |

97.0 |

|

3/4" |

128.0 |

132.0 |

|

7/8 |

194.0 |

203.0 |

|

1 |

287.0 |

333.0 |

|

1 1/8 |

413.0 |

432.0 |

|

1 1/4" |

480.0 |

504.0 |

|

1 ½ |

703.0 |

732.0 |