GENERAL REQUIREMENTS

The intent of this Instructional Memorandum is to address the qualification testing of field welders to weld on any project that requires field welding (structures, bridge repair, piling, railing, casement pipes, etc.)

WELDER QUALIFICATION

Field welders shall be qualified by a test facility with an accredited AWS Certified Welder Program as defined in the current AWS Standard QC 4. Welders shall be qualified per the current QC 7 Standard for AWS Certified Welders. The code of acceptance shall be AWS Bridge Welding Code D1.5. Field welder's qualification herein specified will be considered as remaining in effect from the end of the month in which the test was taken, for a period of 3 years.

Qualification maintenance per applicable AWS Code of Acceptance shall be the responsibility of the certification holder. A copy of the current welder’s certification card from the accredited AWS test facility shall be available to the engineer upon request. The engineer may require requalification if there is specific reason to question the welder’s ability.

Testing will conform to the Iowa Department of Transportation Specifications Article 2408.03, B and AASHTO/AWS D1.5 Bridge Welding Code, Clause 5.

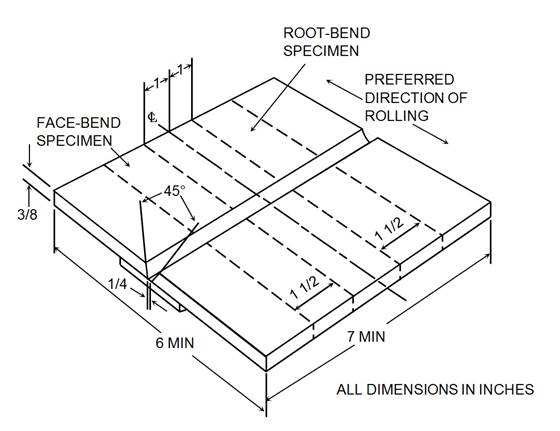

3/8” test plates for the LIMITED thickness test will allow the welder to complete groove welds in material up to and including ¾” thick. The UNLIMITED thickness test is required for material over ¾”. This test requires 1” test plates with a 1/4” to 3/8“ backing bar. A HP 14 X 117 is an example of a steel H-pile that requires the unlimited thickness qualification.

|

POSITION OF TEST WELDS |

|||||||

|

|

|||||||

|

|

|

Type of Weld & Position Of Welding Qualified* |

|||||

|

Qualification Test |

|

|

Plate & Pipe |

||||

|

Weld |

Position |

Groove |

Plate Fillet |

||||

|

|

|

|

|

||||

|

Plate-Groove |

1G |

F |

F, H |

||||

|

|

2G |

F, H |

F, H |

||||

|

|

3G |

F, H, V |

F, H, V |

||||

|

|

4G |

F, OH |

F, H, OH |

||||

|

|

3G & 4G |

All |

All |

||||

|

|

|

|

|

||||

|

*Positions of welding: |

|

|

|||||

|

F=Flat |

1G=Flat Groove |

1F=Flat Fillet |

|||||

|

H=Horizontal |

2G=Horizontal Groove |

2F=Horizontal Fillet |

|||||

|

V=Vertical |

3G=Vertical Groove |

3F=Vertical Fillet |

|||||

|

OH=Overhead |

4G=Overhead Groove |

4F=Overhead Fillet |

|||||

ELECTRODES

Only low-hydrogen electrodes will be permitted for the certification of SMAW welders.

The following list of SMAW, GMAW, or FCAW electrodes are approved for use provided the proper

|

Shielded Metal Arc |

Gas Metal Arc |

Flux-Cored Arc w/External Shielding Gas |

Flux-Cored Arc-Self Shielding |

|

E-XX16 |

ER70S-2, |

|

E6XT-6,8 |

|

E-XX18 |

3, 6 or 7 |

E7XT-1,5 |

E7XT-6,8 |

FAILURE OF TESTS

A welder failing a weld test is immediately disqualified for those positions represented by the test position in which they failed. Retest according to AWS.