GENERAL

Laminated, homogeneous and elastomeric bearing pads shall meet the requirements of Section 4195.02 of the General Specifications. The pad dimensions, laminate positioning, and rubber hardness are shown on the plans. Approved sources are listed in the Materials Approved Products Listing Enterprise (MAPLE).

ACCEPTANCE

Bridge bearing pads will be accepted based on approved Manufacturers (& test reports) and based on certification with Quality assurance monitor sampling and testing as described herein. Successful AASHTO Product Evaluations and Audit Solutions program Audits pursuant to the elastomeric bridge bearing pad workplan will be required to maintain approved status.

Prior to being allowed to furnish pads based on certification, a manufacturer shall comply with the following requirements:

1. Document in writing the quality control procedures utilized at the manufacturing plant.

2. Complete a series of cooperative tests with the departments Materials Testing Laboratory.

3. Successfully complete two shipments of pads into Iowa that have fully complied with the specifications. An extra pad must accompany each shipment for destructive testing purposes. A successful AASHTO Product Evaluations and Audit Solutions program Audit report may be substituted for the two shipments of pads into Iowa as determined by the Construction and materials bureau. A sample pad may be requested for review in this case.

The above requirements are necessary for each type of pad to be furnished, i.e., laminated and homogeneous.

CERTIFICATION PROCEDURE

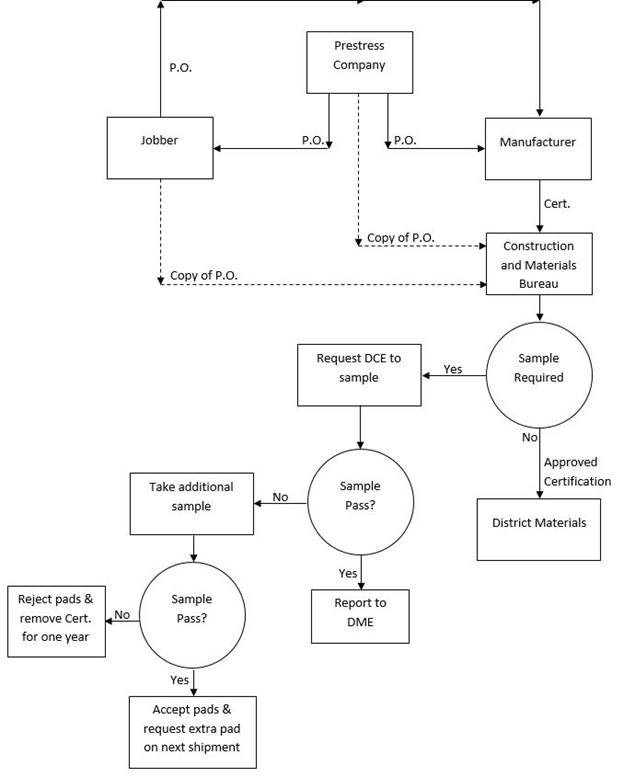

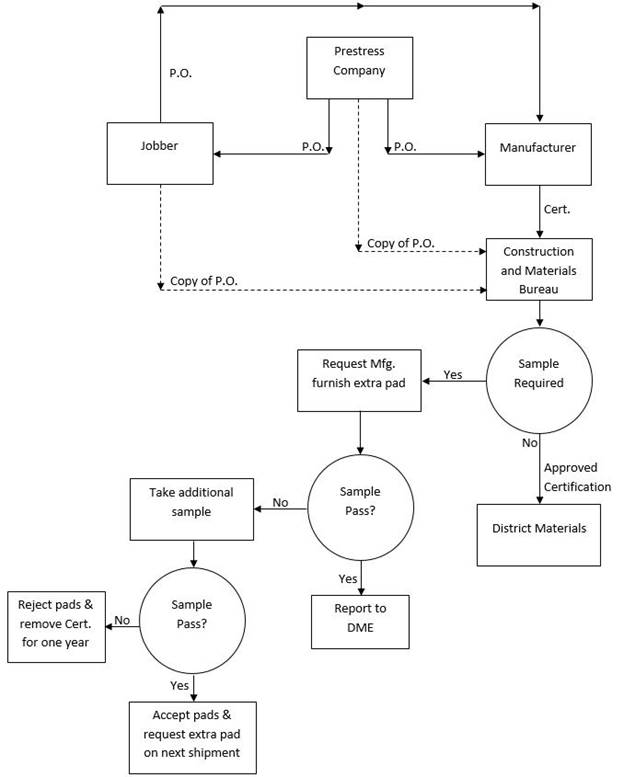

Each pre-stress company ordering bridge bearing pads for use on Department of Transportation projects shall send one copy of their purchase order to the Construction and Materials Bureau, Ames, Iowa, for certification monitoring purposes.

In the event the purchase order is placed with a jobber rather than the manufacturer, the jobber shall also send one copy of their purchase order to the Construction and Materials Bureau in Ames, Iowa.

All purchase orders must state the projects where the pads are to be used, or if the pads will be placed in warehouse stock.

Two copies of the manufacturer certification shall be sent to the Construction and Materials Bureau in Ames, Iowa. The certification shall show the size and number of pads represented, actual test results of the neoprene compound and the grade of steel used for laminates.

MONITOR SAMPLING & TESTING

The amount of monitor sampling and testing will generally depend upon the amount of material supplied by each manufacturer and the time since the last sample was obtained.

A. Sampling Laminated/Elastomeric Pads

When a laminated pad is to be tested, the Construction and Materials Bureau shall notify the manufacturer to furnish one extra pad with shipment. Samples taken are for Quality assurance testing. This is done along with the manufacturer’s inclusion in the AASHTO Product Evaluation and Audit Solutions program. If the pad conforms to the specification no further follow up is warranted. If the pad does not conform to the specification follow up will include notification to the manufacturer and possible additional sample and test at the discretion of the department. (See flow diagram in Figure 1.)

B. Sampling Homogeneous Pads

If a monitor sample is required for homogeneous (non-laminated) pads, an extra pad will be requested of the manufacturer for quality assurance testing purposes. This is done along with the manufacturer’s inclusion in the AASHTO Product evaluation and Audit Solutions Program. The same procedure concerning additional samples, etc. as with laminated pads will be followed. (See flow diagram in Figure 2.)

REPORTING

A copy of an approved certification in the case of shipments furnished by an approved manufacturer, or of the test results in case sampling is required, will be forwarded to the appropriate District Materials Engineer. Based on a certification or test results, approval of pads for a project will be reported by the District Materials Engineer’s Office.

APPROVED SOURCES

Currently approved sources for furnishing bridge bearing pads based on certification are indicated in Appendix C. As indicated in Flowcharts figure 1 and 2, failures of multiple samples from one lot will result in removal from MAPLE.

FIGURE 1. - QUALITY ASSURANCE FOR LAMINATED

NEOPRENE BEARING PADS FROM APPROVED SOURCES

FIGURE 2. - QUALITY ASSURANCE FOR NON-LAMINATED

NEOPRENE BEARING PADS FROM APPROVED SOURCES