****THIS IS A NEW APPENDIX. – PLEASE READ CAREFULLY.****

PRO-RING BY

CRETEX SPECIALITY PRODUCTS

System Description

A. Design Requirements – The manhole grade adjustment rings shall be designed to allow final adjustment of the frame and cover to the grade established by the project plans. The Cretex rings are also designed to accommodate flat or sloping surfaces to within ¼”.

B. Performance Requirements – The Cretex manhole grade adjustment rings shall meet the minimum requirements of AASHTO H-25 and HS-25 loading and shall be resistant to chemicals.

Cretex – Manhole Grade Adjustment Ring

A. The rings are manufactured from ARPRO (Expanded Polypropylene) with a finished density of 7.5 pcf.

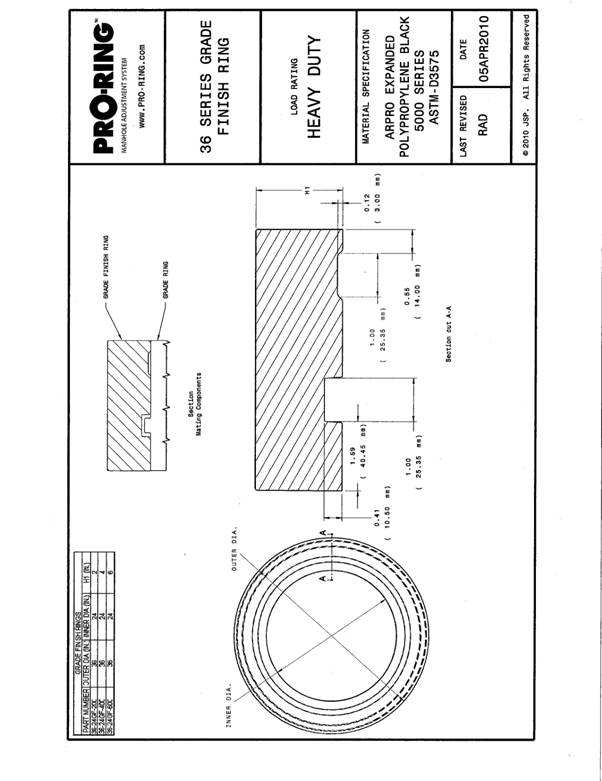

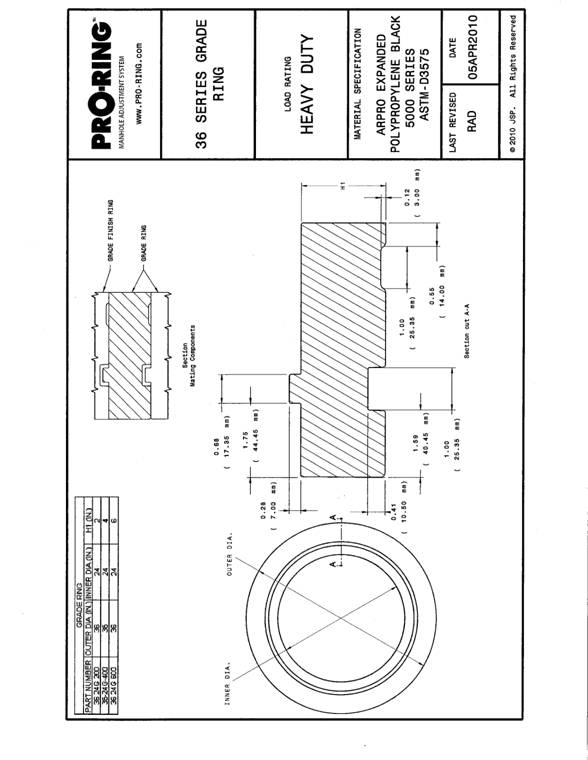

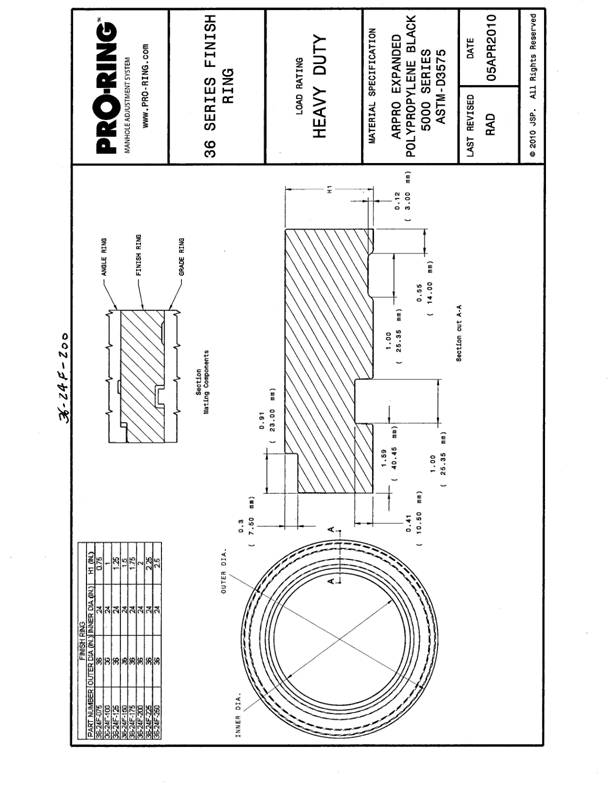

· Grade rings shall have upper and lower keyways (tongue and groove) for upper vertical alignment and sealing.

· Grade rings shall be available in 2, 4, and 6 inch heights.

· Finish rings shall have grooves on the lower surface with a flat upper surface and be available in heights which will allow final adjustment of the frame and cover to within ¼”.

· Angle rings shall be keyed on the lower and upper surface of the ring for proper alignment and mating to “finish” rings and to each other if multiple “angle” rings are required. When and if required the “angle” rings should allow for final adjustment of the frame and cover to within ¼”.

Adhesive/Sealant

Adhesive/sealant should be M-1 structural adhesive/sealant meeting the following requirements:

· ASTM C-920, Type S, Grade NS, Class 25, uses NT, T, M, G, O

· Federal specification TT-S-00230-C Type II, Class A

· Corps of Engineers CRD-C-541, Type II, Class A

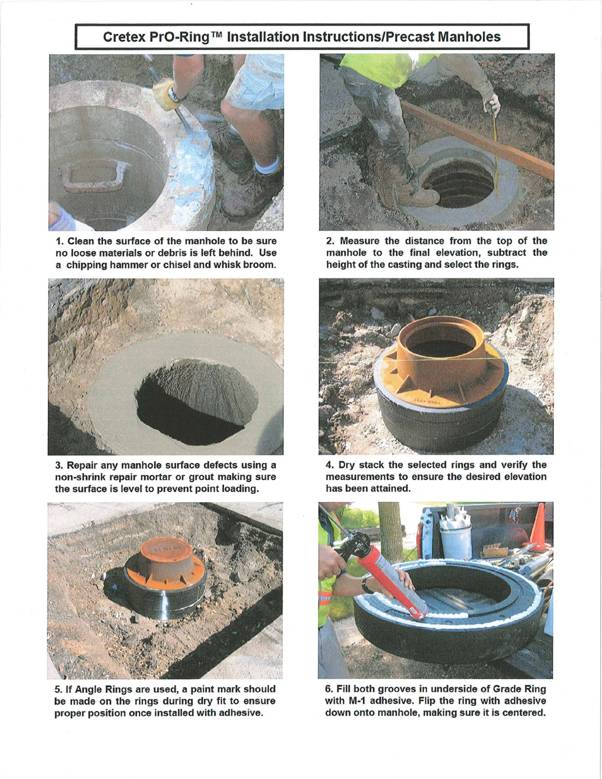

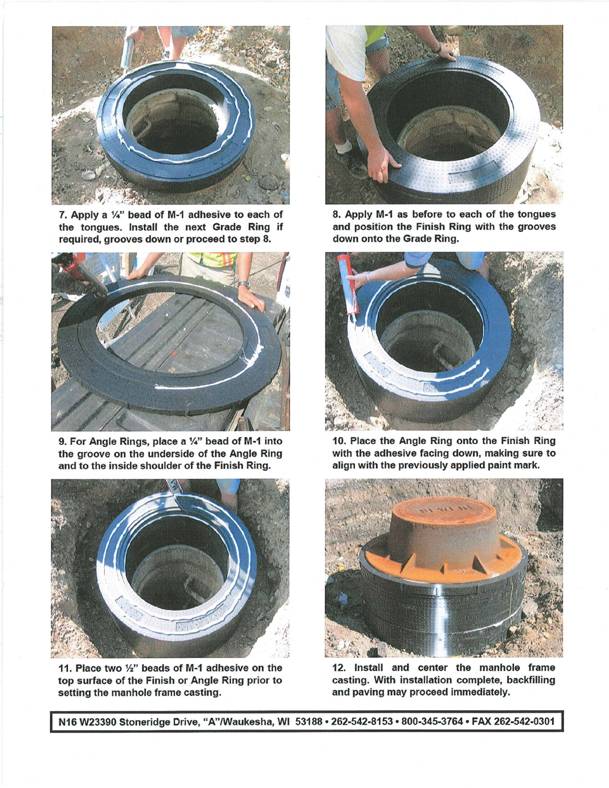

Installation

A. Installation and surface preparation shall be in accordance with manufacturer’s recommendations.

B. The joint between the first grade ring and manhole cone shall be sealed using adhesive/sealant meeting the above listed requirements.

C. The joints between all manhole adjustment rings and the frame cover shall be sealed using adhesive/sealant meeting the above listed requirements.

D. In lieu of the use of an adhesive/sealant, an internal or external mechanical frame-chimney seal may be used for watertight installation.

E. The use of heat shrinkable chimney seal is not permitted by the manufacturer.