RODENT GUARDS / PIPE APRON GUARDS

GENERAL

Rodent guards are intended to keep mice, rats, and other small rodents from entering subdrain outlets, lighting towers, and other areas.

Pipe apron guards are intended to provide a suitable safety guard for the exposed end of pipe culvert.

REQUIREMENTS FOR RODENT GUARDS ON SUBDRAIN OUTLETS

1. The rodent guard shall be constructed of hot-dipped, galvanized steel or aluminum or other approved materials. Galvanizing shall meet the requirements of ASTM A-123.

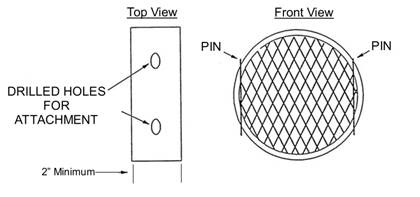

2. The metal ring shall be a minimum of 0.090 in. (2.30 mm) thickness.

3. The ring shall be a minimum width of 2 in. (50 mm) wide for the guards on double walled, polyethylene pipe and a minimum 3.375 in. (85 mm) wide for guards on corrugated metal pipe.

4. The grate shall be a minimum of 17 gauge; 0.054 in. (1.37 mm) expanded sheet metal. The expanded sheet metal can be either flattened or standard.

5. The grate opening shall be a minimum of 0.15 in.2 (95 mm2) and a maximum of 0.25 in.2 (160 mm2).

6. The rodent guard shall be secured to the pipe outlet in a manner such that it can easily be removed and reinstalled.

7. Rodent guards shall meet the requirements of Standard Road Plan RF-19E.

Metal screws may be used in place of pins.

Figure 1: Rodent Guard for Pipe Outlet (Removable Grate)

(Both double-walled plastic and corrugated metal pipe)

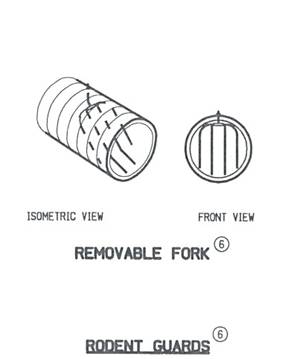

For projects using recycled PCC Subbase, use the removable fork rodent guard.

The fastening mechanism may vary from one manufacturer to another. Approved brands of guards for double-walled polyethylene pipe are listed in Appendix A. Approved brands of guards for corrugated metal pipe are listed in Appendix B.

REQUIREMENTS FOR RODENT GUARDS ON LIGHTING TOWERS & OTHER APPLICATIONS

1. The rodent guard grate shall be of the same material and the same opening size as described for subdrain outlets.

2. The method of attachment will be detailed in the plans.

3. All products of steel and iron shall be of domestic origin and melted and manufactured in the USA.

APPROVAL

Requests for product approval shall be made, in writing, to the Office of Construction and Materials, Iowa Department of Transportation, 800 Lincoln Way, Ames, Iowa 50010. A finished guard shall accompany the approval request. Approval will be based upon test results of the sample. Approved products are identified in the attached appendixes.

MONITOR SAMPLING & TESTING

Samples may be secured from the project and tested to verify compliance.

REQUIREMENTS FOR PIPE APRON GUARDS

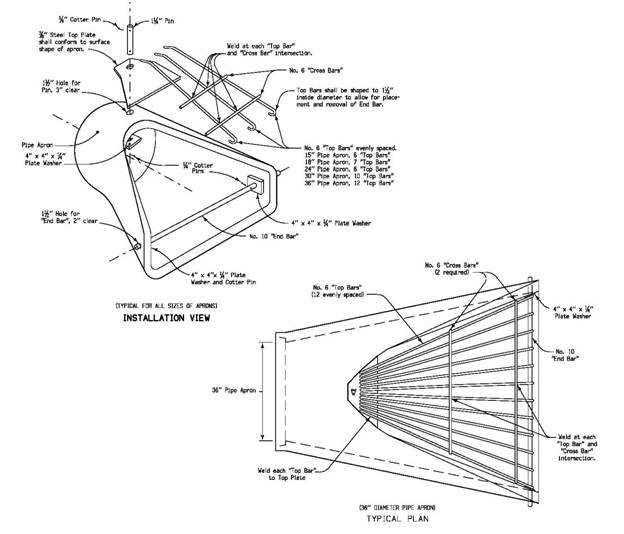

· Pipe Apron Guards shall be constructed by an approved fabricator.

· Pipe Apron Guards shall be constructed of hot dipped galvanized reinforcing steel (smooth or deformed)

· Steel bars used in fabrication of the guard shall meet the requirements of ASTM A 615 Grade 40 or 60, smooth or deformed bars conforming to the fabrication requirements of section 2404 of the standard specifications.

· If welding is employed in placement of reinforcing steel, the welders shall be qualified in accordance with the requirements of Article 2408.13.

For tack welding reinforcing bars, all other requirements shall be as outlined in the latest edition of the AWS code D1.4, including the minimum preheat and interpass temperature except the minimum preheat and interpass temperature shall never be below 50°F (10°C). Any such modification shall be subject to the approval of the engineer.

· Approved weld procedures shall be required. The weld procedure shall remain approved until one of the essential variables has been changed.

· When galvanized reinforcement is required all cutting and bending shall be done before galvanizing.

· The completed Apron Guard shall be hot dip galvanized in accordance with the requirements of ASTM A123. Compliance testing and reporting shall be required.

· Guard’s reinforcement shall be bent accurately to the dimensions, shapes, and requirements of Standard Road Plan RF-26.

· Records of steel mill test reports / certification shall be required for every project.

· All products of steel and iron shall be of domestic origin and melted and manufactured in the USA.

· Fasteners shall meet the following requirements:

o Bolts ASTM A307 Grade A or B, Heavy Hex

o Nuts ATSM A563, Grade DH

o Washers ASTM F463

o Zinc Coating ASTM F2329 (with zinc bath temperature not to exceed 800-850°F.)

Note: Threaded components shall be zinc coated by the same coating process.

APPROVAL

Request for approval shall be made in writing to the Office of Materials. A finished guard shall accompany the request for approval. Approval will be based on sample test results and pertinent certification. Approved sources are listed in Appendix C of this IM.

Pipe Apron Guard